How to Choose the Right Roof Underlayment for Maximum Protection

Roof underlayment is a crucial component of any roofing system. It serves as an additional layer of protection beneath your shingles, guarding against moisture intrusion and improving the durability of your roof. Selecting the right roof underlayment can make a significant difference in the performance and longevity of your roofing system. This article will guide you through the various types of underlayment and provide you with essential factors to consider when making your choice.

Understanding Roof Underlayment

Roof underlayment acts as a barrier between roofing materials and the roofing deck. Its primary role is to protect against water leakage due to rain, snow, or ice, while also serving as a protective layer during insulation installation.

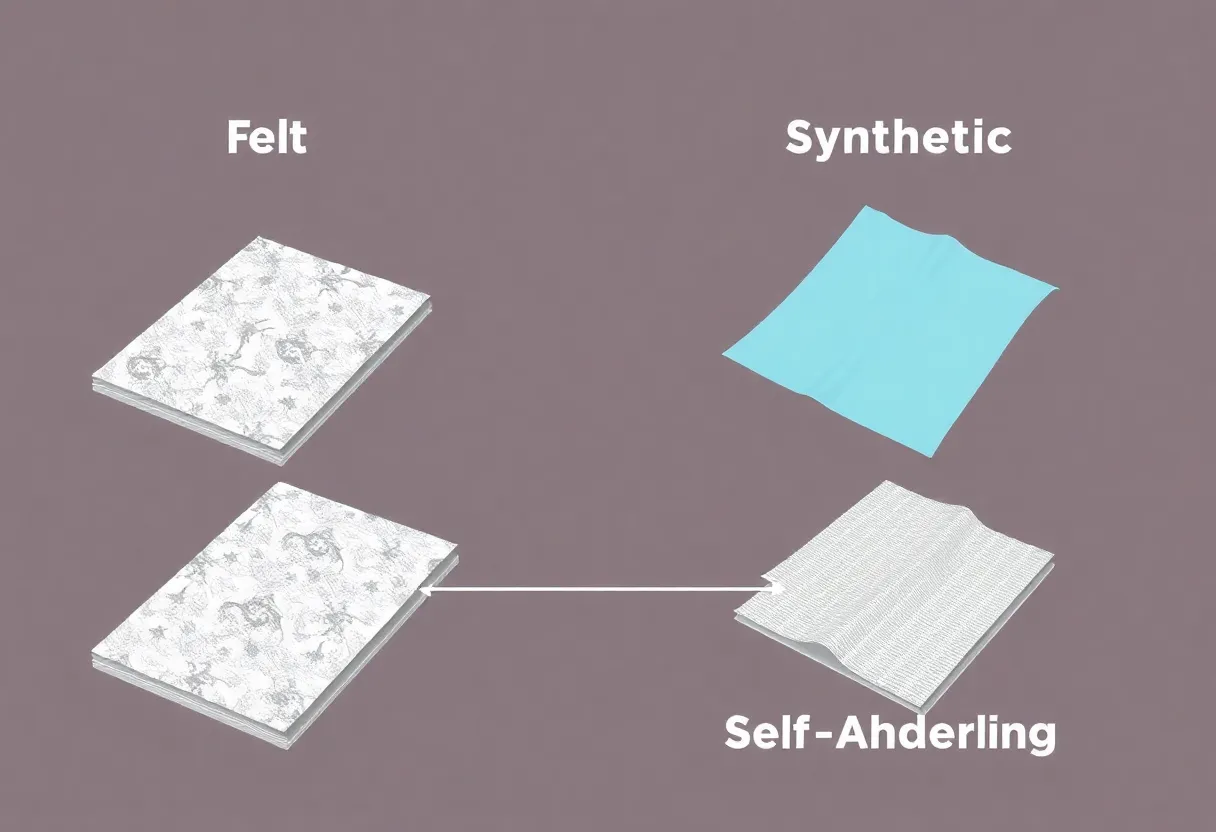

Types of Roof Underlayment

There are three main types of roof underlayment: felt, synthetic, and self-adhering. Each type has unique properties that make them suitable for different roofing applications.

Felt Underlayment

Felt underlayment, often referred to as tar paper, is made from fiberglass or organic materials saturated with asphalt. It is available in various weights, typically 15 or 30 pounds. Its advantages include:

- Cost-effectiveness: Felt is generally less expensive compared to synthetic options.

- Ease of installation: It is easy to cut and lay, making it a preferred choice for many roofing professionals.

- Water resistance: When installed correctly, felt provides substantial water resistance.

However, felt underlayment can be less durable than synthetic varieties and is susceptible to tearing and moisture absorption when exposed to prolonged elements.

Synthetic Underlayment

Synthetic underlayment is made from polypropylene or polyethylene, which gives it enhanced strength and flexibility. Key benefits include:

- Superior durability: Synthetic options outperform felt in tear resistance and long-term reliability.

- Moisture resistance: They are not as prone to absorbing moisture, which can improve the roof’s overall performance.

- Lightweight: Generally lighter than felt, making them easier to handle and install.

Some synthetic products also come with UV protection, allowing them to be exposed to sunlight for a longer period without degrading.

Self-Adhering Underlayment

Self-adhering underlayment is a peel-and-stick product that adheres directly to the roof deck. It offers several advantages:

- Ease of installation: This type can be quickly applied with minimal labor, often requiring no nails or additional fasteners.

- Excellent waterproofing: It creates a solid barrier against water infiltration, preventing leaks under severe weather conditions.

- Long-lasting performance: Self-adhering options are less likely to suffer damage from tearing or movement.

Despite their advantages, self-adhering underlayment may be costlier and require a clean, dry surface for optimal adhesion.

Factors to Consider When Choosing Roof Underlayment

Selecting the right underlayment involves considering several essential factors. These include the type of roofing material, climate, cost, and installation process.

Roofing Material Compatibility

The choice of underlayment can depend heavily on the type of roofing material being used. Certain materials work better with specific types of underlayment.

- Asphalt shingles: Typically use felt or synthetic underlayment.

- Metal roofs: Often require synthetic or self-adhering options for moisture control.

- TPO/EPDM roofs: Benefit significantly from self-adhering or synthetic varieties.

Check with the roofing manufacturer for recommendations to ensure compatibility.

Climate Considerations

Different climates pose unique challenges for roofing systems. Your local weather conditions should guide your choice of underlayment.

- Wet climates: Choose products with high moisture resistance, like synthetic or self-adhering types.

- Hot and sunny climates: Look for underlayment with UV protection to prevent degradation.

- Snowy regions: Ice and water shield products are essential to guard against ice dams.

Cost Implications

Cost is always a consideration, but it shouldn’t be the only factor in choosing underlayment. Here are some points to keep in mind:

- Initial price: Felt tends to be cheaper initially, while synthetic or self-adhering options may have a higher upfront cost.

- Long-term value: Investing in more durable underlayment can reduce repair costs over time.

- Insurance and warranty factors: Some roof systems might influence insurance rates depending on the underlayment selected.

Installation Process

Finally, consider the installation process. Some underlayments require specific installation techniques.

- Felt underlayment: Generally easy to install, but nailing may be needed.

- Synthetic underlayment: Can be rolled out and secured with minimal fasteners.

- Self-adhering underlayment: Requires a clean, dry surface for optimal adhesion, simplifying the process.

Conclusion

Choosing the right roof underlayment is key to maximizing the protection of your roofing system. Evaluate factors like roofing material compatibility, climate conditions, cost implications, and the complexity of the installation process. Each type of underlayment—felt, synthetic, or self-adhering—offers distinct advantages and disadvantages. Always consider your specific needs and conditions to select the best option. Taking these steps will ensure that you protect your home investment effectively.

Author: STAFF HERE IRMO

The HERE Irmo Staff Writers are a collaborative team of journalists, editors, and local contributors passionate about delivering accurate, timely information to the Irmo community. As part of the HEREcity.com Network, which powers over 100 U.S. city sites including HEREcolumbia.com, our staff draws on collective experience in South Carolina journalism to cover everything from business sales and real estate developments to dining deals and community initiatives. Our Expertise and Background Local Roots in Irmo Our team includes lifelong Irmo residents and SC natives with deep knowledge of the area’s history, economy, and culture. We’ve covered key events like the recent developments around Lake Murray, Irmo’s community festivals like the Okra Strut, and growth in local education sectors (e.g., Midlands Technical College programs). Collective Experience With over 50 combined years in journalism, our staff has backgrounds in print, digital media, and community reporting. We prioritize fact-based stories, drawing from sources like the Irmo Chamber of Commerce, town government records, and on-the-ground interviews. Commitment to Quality Every article is a group effort, involving research, editing, and verification to ensure reliability. We adhere to journalistic standards, citing credible sources and updating content as new details emerge.

Mays Contracting

Mays Contracting